Denkar

Production

The production of the company “DENKAR” is located on an area of over 4000 sq.m, the equipment and metalworking machines fleet has more than 100 units.

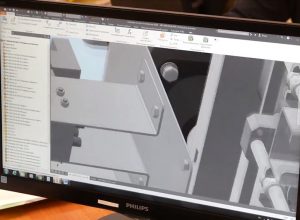

1. Design preparation of models

The design of equipment models in the company is performed by experienced design engineers who are proficient in the most modern 3D modeling programs.

2. Blank production shop

In the blank shop, works on the manufacture of equipment parts are performed: bending, laser cutting, turning and milling, welding, painting.

3. Assembly shop.

Highly qualified electronics engineers, electrical fitters, mechanics, fitters, assemblers work in the assembly shop, who ensure the quality, reliability and durability of the manufactured equipment. In fact, in this shop the final stage of the production process takes place.

4. Technical Control Department.

Each manufactured product undergoes independent control for compliance with the requirements and guarantees this compliance to our customers.