Cost (including VAT)

- 1,190,000 rubles.

Guarantee

- Warranty period - 12 months

Description

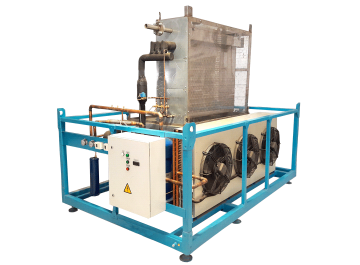

Panel film evaporator for 4 plateaus with a heat exchange surface area of 9 sq. m. It is intended for cooling water and other liquids used further in technological processes at food industry enterprises (dairy, brewing, poultry, meat, fish processing plants), chemical industry. Main application: cooling water to temperatures close to 0°C, without the risk of defrosting the heat exchanger.

Cooling method: The liquid is cooled by flowing under the influence of gravity along the outer surface of vertically installed heat exchange panels.

In special cases, it is possible to directly cool liquids such as juice, wine, beer, milk, as well as contaminated water.

The product is intended for use in areas with temperate and cold climates of the UHL placement category 4 according to GOST 15150-69.

The composition of the evaporator installation

- Storage tank

- Heat exchange module

- Spiral compressor

- Air heat exchanger (condenser)

- Water heat exchanger (panel)

- Temperature control valve

- Auxiliary elements

- Receiver

- Liquid separator

- Filter dryer

- Oil separator

- Control systems

- Electric shield

- Temperature sensor

During installation, it is only necessary to connect the power supply to the electrical panel and connect the pipelines with the coolant.

To ensure uninterrupted operation of the panel evaporator in automatic mode, the controller is programmed to set the set temperature of the water in the tank. The electric shield provides the main protective functions of the refrigeration unit.