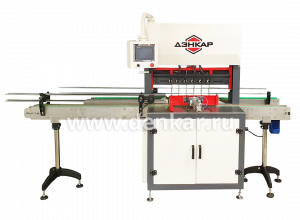

Semi-automatic machine for filling liquids PMR-1000

Designed for filling containers with various liquids, including semi-viscous ones.

The equipment for filling lines produced by DENKAR is designed using the latest technology and equipped with components from reliable global manufacturers.

Having its own design department and being a manufacturer of filling equipment, our company has the opportunity to constantly revise, improve and modernize the equipment produced.

In the DENKAR carbonated beverage filling line, special attention is paid to the qualitative characteristics of the filling process, such as dosing accuracy, prevention of foam and drop formation, reduction of product and container losses, and the level of hygiene of the filling process.

All parts in contact with the product are made of quality stainless steel and materials approved for use in the food industry.

Filling machines, saturation units, labeling machines, capping machines, elevators-orientators – all machines are individually tested, adjusted and commissioned by our specialists.

Watch a video overview of how the complete equipment works:

You can purchase a complete set of equipment “turnkey” as well as each machine separately. It is possible to manufacture casting equipment according to individual orders.

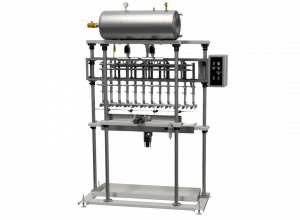

Designed for filling containers with various liquids, including semi-viscous ones.

The machine is designed for filling various liquids in PET containers with a volume of 0.5 to 3.0 liters. Capacity 1500 l/hour

The machine is designed for packing carbonated drinks in PET containers with a volume of 0.33 to 2.0 liters. Capacity from 2000 to 3000 btu./hour

Automatic machine for filling water and drinks with syrup into bottles made of polyethylene terephthalate (PET containers) with a capacity from 2000 to 3000 bottles/hour

The machine is designed for sealing PET bottles (0.25-2L) with a screw plastic stopper.

The elevator-orientator is designed for sampling the cap from the hopper, orientation and feeding it to the sample feeder.

The machine is designed for sealing PET bottles (4-6 l.) with a screw plastic stopper

The ET-3000 labeling machine is designed for applying an annular polypropylene label to a cylindrical PET bottle.

Designed for automatic application of labels, stickers, signs, holograms, and other marking products with a self-adhesive base, on almost any surface.

The labeling machine is designed for automatic simultaneous labeling of three labels on products moving along the conveyor.