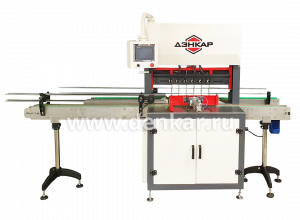

CA-1000 capping machine

The machine is designed for sealing PET bottles (4-6 l.) with a screw plastic stopper

The machine is designed for sealing PET bottles (4-6 l.) with a screw plastic stopper

Designed for automatic application of labels, stickers, signs, holograms, and other marking products with a self-adhesive base, on almost any surface.

The elevator-orientator is designed for sampling the cap from the hopper, orientation and feeding it to the sample feeder.

The machine is designed for filling various liquids in PET containers with a volume of 0.5 to 3.0 liters. Capacity 1500 l/hour

Designed for filling containers with various liquids, including semi-viscous ones.

It is intended for group and piece packaging in shrink-wrapped polyethylene film of cable coils, boxes, bottles, PET containers, packaged goods, etc.

It is intended for group and piece packaging in shrink-wrapped polyethylene film of cable coils, boxes, bottles, PET containers, packaged goods, etc.

It is intended for group and piece packaging in shrink-wrapped polyethylene film of cable coils, boxes, bottles, PET containers, packaged goods, etc.

It is intended for group and piece packaging in shrink-wrapped polyethylene film of cable coils, boxes, bottles, PET containers, packaged goods, as well as printing.

The TM-1A Direct-flow thermal packaging line is designed for automatic group packaging of food, cosmetic or other products in glass, metal, paper or plastic containers: cans, PET bottles, cans, boxes, bags, etc.

TM 1 thermal packaging machine-Automatic Direct-flow LED is designed for automatic group packaging of food, cosmetic or other products in glass, metal, paper or plastic containers: cans, PET bottles, cans, boxes, bags, etc. Main Features: Performance up to 22 cycles/min; Conversion to a different type of product takes 15 minutes;…

Designed for packaging food, cosmetic or other products in glass, metal, paper or plastic containers.

Thermal packaging machine TM-1A (automatic) is designed for automatic group packaging in shrink wrap of food, cosmetic or other products in glass, metal, paper or plastic containers. Full automation simplifies the work of the operator and does not require direct participation in the operation of the thermal packaging machine.