Bactericidal irradiator OBK-30

Module description

The germicidal irradiator OBK-30 is a closed-type irradiator. It is used for disinfection of PET containers and is installed on the conveyor system.

Irradiation is performed by a bactericidal lamp, which emits UV radiation with a wavelength of 253.7 nm, destructive to various bacteria, viruses and microorganisms on the surfaces and in the air.

Protection class from electric shock according to GOST 12.2.025-76 class I, type H. Type of climatic modification UHL 4.2 according to GOST 15150-69.

| Nominal lamp power, W | 30 |

| Power consumption not more than, W | 65 |

| Supply voltage, V/Hz | 220/50 |

| Starter type | S10 |

| Lamp capacity, m³/hr | 50 |

| The average duration of the lamp, hour. | 8000 |

| Maximum overall dimensions (DxHxV), mm | 1240х410х630 |

| Product weight, kg | 10 |

Automatic machine for bottling liquids LRM-1000

Module description

The DRM-1000 liquid filling machine is an autonomous device designed for filling containers with various liquids. Liquids should not be strongly foaming and aggressive. It is allowed to pour semi-viscous liquid.

- The DRM-1000 liquid filling machine has an operator panel on which all the necessary settings are displayed;

- Adjustment of the liquid filling speed;

- There is a drip collector designed to prevent the spilled liquid from getting on the outside of the container.

| Maximum capacity (for a 5 l container), bottles / hour | 1000 |

| Fillable container volume, l | 4-6 |

| Supply voltage, V/Hz | 380/50 |

| Power consumption not more than kW | 2,2 |

| Overall dimensions (DxHxV), mm | 1335х1050х2040 |

| Number of filling heads, pcs. | 6 |

| Installation weight, kg | 300 |

| Working pressure of compressed air, MPa | 0,6-0,8 |

CA-1000 capping machine

Module description

The machine is designed for sealing PET bottles (4-6 liters) with a screw plastic stopper. The capping machine is equipped with an operator panel, which is used to display data on work processes and make adjustments to the operation of the machine through the display.

- A wide range of types of corked bottles;

- The possibility of capping various types of lids thanks to the easy-to-change head;

- Reliable and gentle sealing of containers thanks to the Camozzi pneumatic system;

- The ability to adjust the twist force;

- The ability to adjust the capping performance.

<

| Rated capacity, bottles/h | 1000 |

| Working pressure of compressed air, MPa | 0,6-0,8 |

| Air flow rate (at nominal pressure), l/min | 250 |

| Supply voltage, V | 380 |

| Power consumption, kW | 0,5 |

| Total weight not more than, kg | 150 |

| Overall dimensions (DxHxV), mm | 1100х700х2000 |

| Permissible defect percentage, % | 0,5 |

Elevator-orientator cap EO-1000

Module description

The elevator-orientator is designed for sampling the cap from the hopper, orientation and feeding it to the sample feeder.

The capacity of the hopper is up to 1500 pieces of plugs.

- Easy installation, easily integrated into any filling lines;

- Large volume of the hopper under the lid.

| Rated capacity, caps/h | 1000 |

| Power consumption not more than kW | 0,12 |

| Overall dimensions (DxHxV), mm | 1250х600х2500 |

| Weight, kg | 120 |

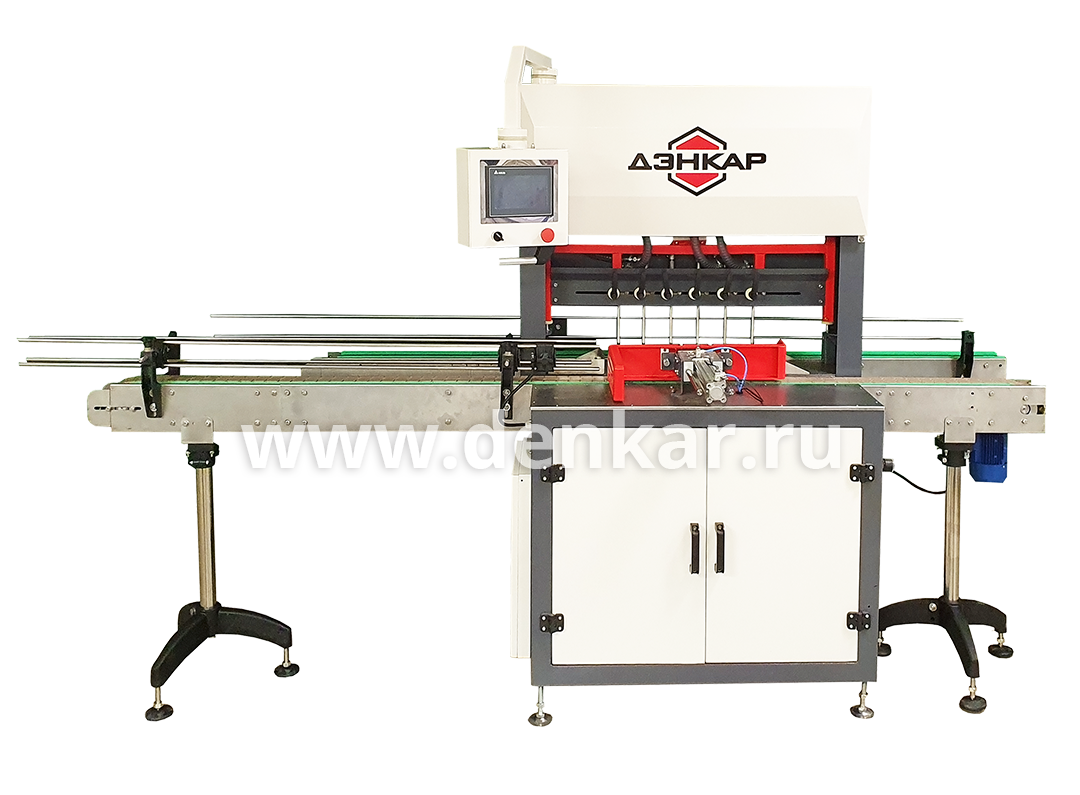

ETS-3000 labeling machine

Module description

The ITS-3000 labeling machine is designed for automatic application of labels, stickers, signs, holograms, and other marking products with a self-adhesive base, on almost any surface (bottles, cans, vials, boxes, etc.).

- Speed and accuracy of label application;

- Easy setup and operation of the labeler itself;

- The labeling machine can be integrated into an existing system;

- High reliability and durability of the labeling machine;

- The machine can be equipped with a thermal jet printer for applying the date;

- The machine can be equipped with a rolling conveyor for circular label application.

<

| Maximum circumferential label feed rate, m\min | 22 |

| Maximum label height, mm | 150 |

| Label length, mm | 10…1000 |

| Inner diameter of the label reel, mm | 76 |

| Outer diameter of label reel, mm | 300 |

| Distance between labels (min), mm | 3 |

| Top and bottom margins (min), mm | 2,5 |

| Power consumption, kW | 0,15 |

| Voltage, V/Hz | 220/50 |

| Overall dimensions (DxHxV), mm | 810х700х1250 |

| Weight, kg | 50 |

Conveyor unit TR-15000

Module description

The transportation conveyor for bottles is used as part of automated lines for moving bottles in the horizontal plane.

It is the main element connecting all the equipment installed in the filling line into a single chain: from blowing to thermal packaging of finished products.

- smooth adjustment of the belt speed;

- easy embeddability in the working line;

- high reliability and build quality;

- easy maintenance.

| Overall dimensions (DxHxV), mm | 15000х216х900 |

| Base material of the conveyor unit | Stainless steel |

| Belt width, mm | 190 |

| Tape material | Plastics |

| Belt speed, m/min | 4-8 |

| Power consumption, kW | 0,25 |

| Weight, kg | 200 |

| Voltage, V/Hz | 380/50 |

Packaging machine TM-1A (190 mm)

Module description

Thermal packaging machine TM-1A (automatic machine) is designed for automatic batch shrink-wrapping of PET water bottles (bottle volume 5 liters).

Full automation simplifies the work of the operator and does not require direct participation in the process of the heat shrink wrapping machine.

| Dimensions of the complete machine (LxWxH), mm | 5160x2800x2260 |

| Required capacity of the line, units/hour | 600 |

| Maximum dimensions of packaged products (DxHxV), mm | 350х150х360 |

| Machine weight, kg | 680 |

| Type of thermowell/thermowell control unit | Separate |

| Power supply parameters, V/Hz | 380/50 |

| Heating temperature control range, °C | 20-220 |

| Chamber length, mm | 1200 |

| Dimensions of the chamber passage window (WxH), mm | 600х400 |

| Product delivery direction | From left to right |

| Welding type | Permanent |

The cost of the line: Check with your manager

Leave a requestThe manufacturing time of the filling line is 40-50 working days.